A big thank you to everyone who submitted an image in the 2023 RTNN Image Competition. We are excited to announce the winners. These images were submitted as part of the annual NNCI Image Contest, There’s Plenty of Beauty at the Bottom.

These images will be submitted to the next level to compete at the national level of submissions across all of the NNCI. Please make sure to go to the NNCI website and vote for your favorites! Voting closes October 17, 2023.

Vote here: https://nnci.net/plenty-beauty-bottom

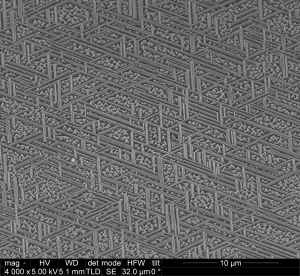

Most Stunning

Perovskite Crop Circles

Alicia Bryan, UNC-Chapel Hill

Methylammonium lead iodide (MAPbI3) perovskite deposited on a mica substrate via chemical vapor deposition, demonstrating epitaxial rod-like structures and pyramidal crystallites. Image taken on FEI Helios 600 Nanolab Dual Beam System with a surface tilt of 45 degrees.

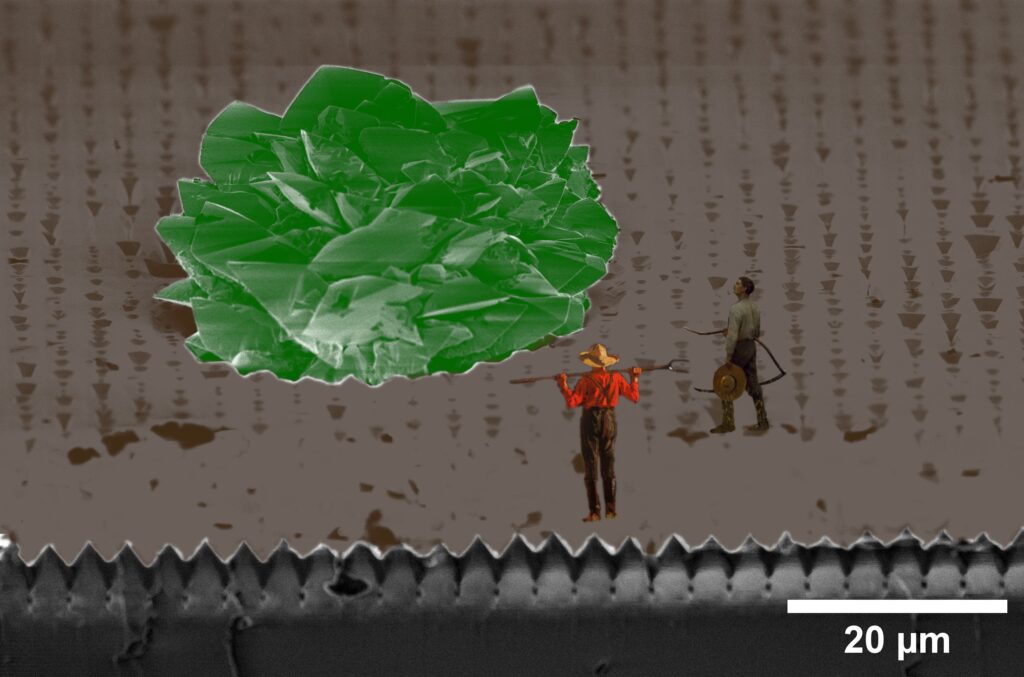

Most Whimsical

Giant Cabbage

Jack Almeter and James Loveless, NC State University

This image depicts an overhead view of an attempt to epitaxially coalesce AlGaN over GaN ridges. Coalescence was not complete, resulting in trenches reminiscent of furrowed farmland. Rogue nucleation has occurred at one point, perhaps due to contamination or an irregularity in the pattern. This large crystallite has an organic shape, here imagined as a giant cabbage worthy of the NC State Fair. A pair of farmers, taken from “Farmer with a Pitchfork” and “Song of the Lark” by 19th century American painter Winslow Homer, marvel at the vegetable in the foreground.

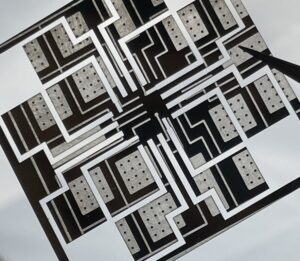

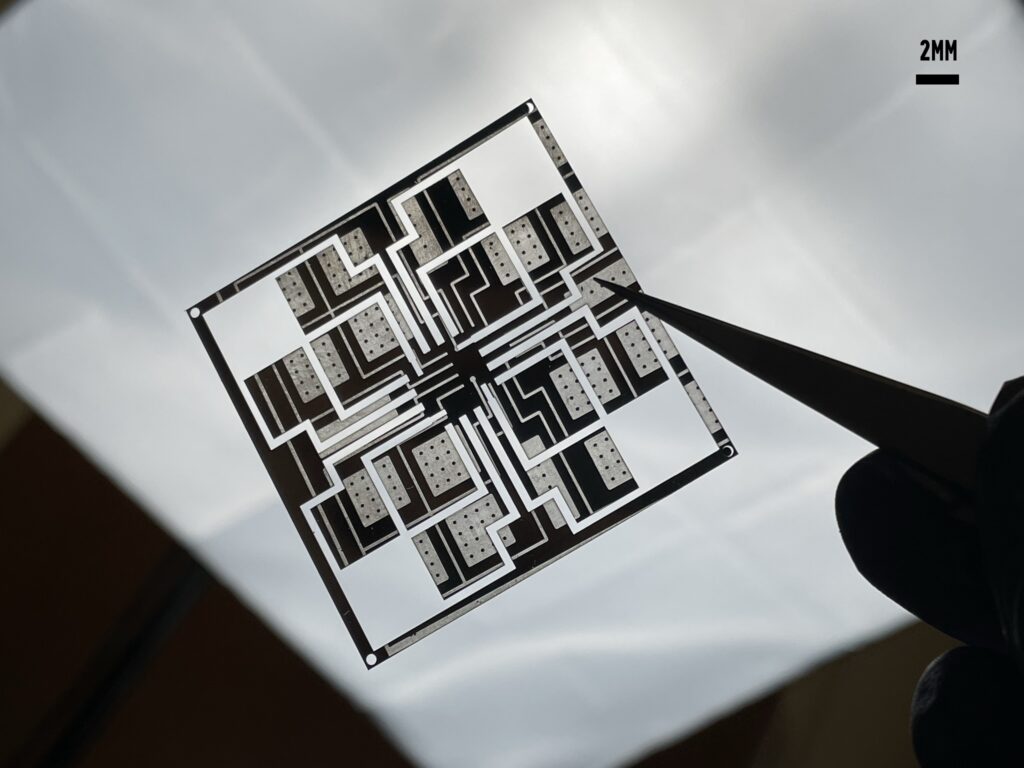

Most Unique Capability

A Witness of Evolution

Kyle Pan, Duke University

This plastic sheet, with its futuristic look, is now a living canvas of our soft morphing robots’ evolution. Its journey commenced as a mere glass cover sheet in the electron beam evaporation process, during the fabrication of our soft robot’s sensing functionalities. As the design progressed, we embraced an air-pocket design, and this sheet transformed into a photolithography mask, resulting in its various patterns on the sheet. Now, as we further improved in the soft robot fabrication, this resilient sheet stands as a laser-cut mask for oxidized liquid metal, capturing the essence of progress in our research.